In the ever-evolving landscape of manufacturing, 3D printing technology, also known as additive manufacturing, has positioned itself as a cornerstone of innovation. This transformative technology has the remarkable capability of turning digital models into tangible three-dimensional objects by adding material layer by layer. The versatility and efficiency of 3D printing have revolutionized the traditional manufacturing processes across a wide array of industries including automotive, healthcare, aerospace, and consumer goods. It is redefining the paradigms of design, production, customization, and even supply chain logistics, making it a pivotal force in the future of manufacturing.

Introduction to 3D Printing Technology

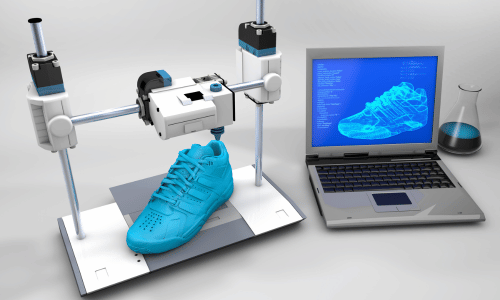

At its core, 3D printing, or additive manufacturing, is a revolutionary process that fabricates three-dimensional solid objects from a digital file. This technology stands in stark contrast to traditional subtractive manufacturing methodologies, which typically involve cutting away at a solid block of material to achieve the desired shape. Instead, 3D printing adds material in a precise, layer-by-layer fashion to build objects. This method offers unparalleled flexibility in manufacturing, enabling the creation of complex and intricate designs that would be difficult, if not impossible, to achieve with conventional techniques. Furthermore, it introduces significant efficiencies by minimizing waste and reducing the materials used, thereby also aligning with sustainable manufacturing practices.

Transforming Prototyping and Product Development

The advent of 3D printing has brought about a seismic shift in prototyping and product development. Traditional methods of prototyping were not only costly but also time-consuming, limiting the ability of engineers and designers to iterate and refine their concepts rapidly. 3D printing technology has demolished these barriers, enabling the swift production of prototypes that closely mimic the functionality and aesthetics of the intended final product. This rapid prototyping capability facilitates a more dynamic and iterative design process, significantly accelerating the path from concept to commercialization. In essence, 3D printing empowers creators to bring their visions to life with greater speed and lower costs, fostering an environment ripe for innovation and creativity.

Customization and On-Demand Production

In a world where consumer preferences are increasingly leaning towards personalized products, 3D printing shines as a beacon of customization. This technology allows for the cost-effective production of items tailored to individual specifications without the need for expensive tooling or moulds. The implications of this are profound, spanning various sectors from medical devices, such as bespoke prosthetics and implants, to personalized automotive components and even customized fashion accessories. Moreover, 3D printing supports a lean manufacturing model, enabling on-demand production that mitigates the need for extensive inventories and reduces the waste associated with overproduction.

Advancing Materials and Sustainability

One of the most exciting developments in the realm of 3D printing is the continuous innovation in materials. Today, a wide variety of materials can be used in 3D printing, including thermoplastics, resins, metals, and even composites, expanding the technology’s applicability across industries. These materials are not only getting stronger and more versatile but also more environmentally friendly. The ability to use biodegradable materials or recycle used materials for new prints is a testament to the sustainable potential of 3D printing. It aligns perfectly with the global shift towards sustainability in manufacturing, reducing the environmental footprint of production processes.

Challenges and Future Directions

Despite its vast potential, 3D printing does not come without its set of challenges. The high cost of equipment and the need for specialized skills to operate 3D printing machinery can be barriers to widespread adoption. Furthermore, the current pace of production and the limited availability of certain materials can restrict its application in mass production scenarios. However, continuous advancements in 3D printing technology, materials science, and software are systematically addressing these issues, broadening the scope and accessibility of this innovative manufacturing approach.

The future of 3D printing in manufacturing is not just promising but is poised to redefine what is possible in design and production. With the advent of multi-material printing, the potential for creating more complex and functional products is expanding. Moreover, as the technology becomes more integrated with other manufacturing processes and the Internet of Things (IoT), it will further enhance efficiency and customization, heralding a new era of smart manufacturing.

Conclusion

The role of 3D printing in manufacturing innovation cannot be overstated. It is revolutionizing how products are designed, prototyped, and produced, offering unprecedented flexibility and efficiency. As the technology continues to evolve and mature, its impact on the manufacturing industry will only grow, pushing the boundaries of innovation and opening new frontiers in production capabilities. The journey of 3D printing from a novel prototyping tool to a fundamental component of manufacturing underscores its transformative potential, marking it as an essential element of the next industrial revolution.

We’ve unpacked a lot today at Biz Step Ladder, and now it’s your turn to add to the dialogue. Do you have insights or experiences that could expand on what we’ve discussed? Perhaps you’ve identified an angle we haven’t covered. Jump into the conversation below with your comments and let’s continue the learning journey together. Your input is not just welcome—it’s a vital part of our community’s growth. So, what are your thoughts? Share them below and let’s enrich our business wisdom collectively!

Discover related content by exploring Mastering Entrepreneurial Success in the Digital Economy